Floating Platforms with Lightweight Aggregates

ECA® – Expanded Clay Aggregate is revolutionizing marine construction by enabling the creation of innovative floating platforms. In today’s dynamic construction environment, sustainable, lightweight, and robust materials are key to building modern floating structures that cater to both industrial and recreational applications. ECA® is at the forefront of this transformation, offering advanced solutions for buoyant structural components and modular waterborne structures. By integrating ECA® into these applications, engineers and architects can achieve superior performance with reduced structural loads, enhanced durability, and remarkable environmental benefits.

Transforming Buoyant Structural Components

Floating Innovation with ECA®

Buoyant structural components form the backbone of any floating platform, providing the necessary lift and stability while ensuring structural integrity. ECA® – Expanded Clay Aggregate is a game changer in this field, offering a lightweight yet strong alternative to traditional materials. The unique characteristics of ECA®, including its engineered porosity, optimized bulk density, and high water retention capacity, enable the production of buoyant elements that support significant loads without excessive weight.

When incorporated into concrete mixes, ECA® reduces overall mass while maintaining high compressive strength. This property is critical for floating structures, where minimizing weight is as important as ensuring long-term durability.

- Porosity refers to the proportion of void spaces in the material that enhances buoyancy and insulation

- Bulk density is the material’s weight per unit volume, impacting the load

- Water retention capacity measures the material’s ability to hold water during curing

- Compressive strength indicates the material’s resistance to crushing forces.

These buoyant components not only improve performance under dynamic marine conditions but also enable cost savings in transportation and installation. By lowering the structural load, ECA® facilitates the design of more efficient and economical floating platforms that can adapt to a variety of environments.

Advancing Modular Waterborne Structures

Designing Versatile Floating Systems

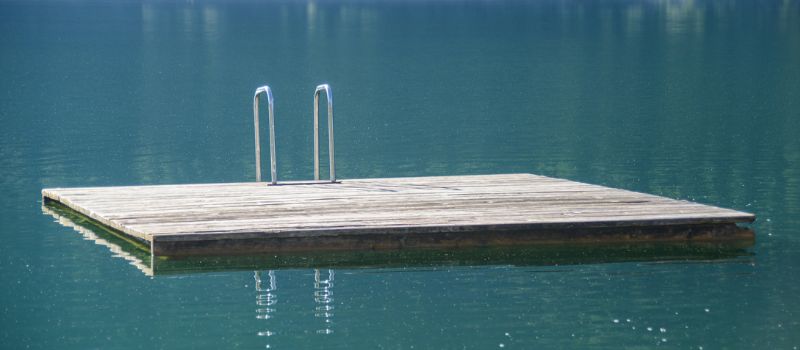

Modular waterborne structures offer flexibility, scalability, and rapid assembly in marine construction. ECA® – Expanded Clay Aggregate is ideally suited for such applications, thanks to its lightweight properties and high performance. Modular systems built with ECA® provide consistent quality and performance, making them ideal for use in docks, floating offices, recreational platforms, and emergency response units.

ECA® contributes to modular waterborne structures by ensuring a uniform curing process in concrete, leading to consistent compressive strength across all components. Its low bulk density minimizes the overall weight, facilitating easy assembly and reconfiguration of modules to meet evolving needs. Additionally, the material’s high water retention capacity enhances the hydration process, resulting in improved durability and longevity of the structure.

Modular waterborne structures designed with ECA® not only deliver excellent structural performance but also reduce maintenance and operational costs over time. Their adaptability makes them a smart investment for projects where flexibility and efficiency are paramount.

Driving Sustainability with ECA®

Building a Greener Future on Water

Sustainability is a central pillar in modern construction and ECA® – Expanded Clay Aggregate plays a pivotal role in reducing the environmental impact of floating platforms. The lightweight nature of ECA® means that less material is required, resulting in lower transportation energy and a reduced carbon footprint during installation. Moreover, the superior performance of ECA® translates into longer-lasting structures that require less maintenance, further decreasing their environmental impact over time.

ECA® is manufactured through processes designed to minimize resource waste and energy consumption, making it an eco‑friendly choice for marine construction. Its unique properties, such as high water retention capacity and controlled porosity, contribute to a uniform curing process and enhanced compressive strength, ensuring that the structures not only meet but exceed performance standards while promoting sustainability.

- Carbon footprint refers to the total greenhouse gas emissions caused directly or indirectly by the production and use of a material

- Eco‑friendly implies that the material has minimal negative impact on the environment.

By choosing ECA® for buoyant structural components and modular waterborne structures, builders can align their projects with green building initiatives, achieving certification under schemes like LEED without compromising on quality or performance.

Overcoming Operational Inefficiencies

Streamlining Marine Construction with Consistent Material Performance

Marine construction projects often face challenges related to material variability and inconsistent curing processes, which can lead to increased costs and delays. ECA® – Expanded Clay Aggregate overcomes these obstacles by providing a consistently high-quality material that standardizes production across floating platforms. Its precisely engineered porosity and bulk density ensure that every component of a floating platform behaves predictably, reducing the need for extensive quality control and rework.

The consistent performance of ECA® leads to a more reliable curing process, resulting in uniform compressive strength across all structural elements. This reliability is particularly important for modular waterborne structures, where each module must perform to the same high standard to ensure overall system integrity.

- Quality control in marine construction refers to the processes that ensure materials meet the required standards

- Uniform compressive strength indicates consistent load-bearing capacity across all elements.

By addressing these operational gaps, ECA® not only improves the efficiency of the construction process but also lowers overall project costs by reducing material waste and minimizing maintenance requirements. The streamlined production enabled by ECA® is a significant competitive advantage in an industry where time and quality are critical.

Additional Values: Aesthetic Versatility and Enhanced Safety

Integrating Aesthetics and Performance in Floating Platforms

Beyond structural and environmental performance, ECA® – Expanded Clay Aggregate adds significant aesthetic and functional value to floating platforms. The inherent texture of ECA® imparts a natural, contemporary look to buoyant structural components, enhancing the visual appeal of the platform without compromising its durability. This aesthetic versatility is crucial in applications where appearance is as important as performance, such as recreational or commercial floating structures.

Moreover, the lightweight properties of ECA® contribute to enhanced safety by reducing the risk of structural overload during dynamic marine conditions. The material’s excellent compressive strength and uniform curing process ensure that floating platforms can withstand the rigors of harsh weather and operational stresses, providing a safe and resilient foundation for various waterborne applications.

Additionally, the eco‑friendly nature of ECA® supports sustainable design, making it a preferred choice for projects that aim to minimize their environmental footprint while delivering high-quality, safe, and visually appealing structures.

Lightweight porous aggregates provide natural buoyancy, making them ideal for floating structural platforms and modular waterborne construction. Their low density and durability enable architects and engineers to design buoyant structural components and eco-friendly floating systems for marinas, artificial islands, and waterfront developments. By using expanded clay aggregates, floating platforms become more sustainable, stable, and adaptable to diverse aquatic environments.

FAQ & Technical Insights: Floating Platform Innovation

ECA® is integrated into floating platforms to reduce weight and enhance the compressive strength and durability of buoyant structural components and modular waterborne structures.

Compressive strength is the material’s ability to resist crushing forces.

Its lightweight properties reduce the overall mass of the structure, lowering energy consumption during transportation and installation while also enhancing the thermal insulation of the platform.

ECA®’s engineered porosity, optimized bulk density, high water retention capacity, and superior compressive strength ensure a robust, durable, and lightweight material for floating platforms.

ECA® enables the creation of modular structures that are easy to assemble, reconfigure, and maintain, due to its consistent curing properties and enhanced water retention capacity.

By optimizing porosity and bulk density, ECA® creates lightweight, high‑performance components that provide excellent buoyancy and stability in marine environments.

Elevate Your Floating Platforms with ECA®

ECA® – Expanded Clay Aggregate stands at the cutting edge of marine construction technology. Its innovative properties enable the production of floating platforms that combine lightweight performance, exceptional durability, and environmental sustainability. Whether used in buoyant structural components or modular waterborne structures, ECA® provides a transformative solution that reduces structural loads, improves consistency in material performance, and supports eco‑friendly design. By integrating ECA® into your floating platform projects, you not only achieve superior engineering outcomes but also contribute to a sustainable future in marine construction.